Address

KOZDIS Electric & Technology

Boca Raton, FL 33496

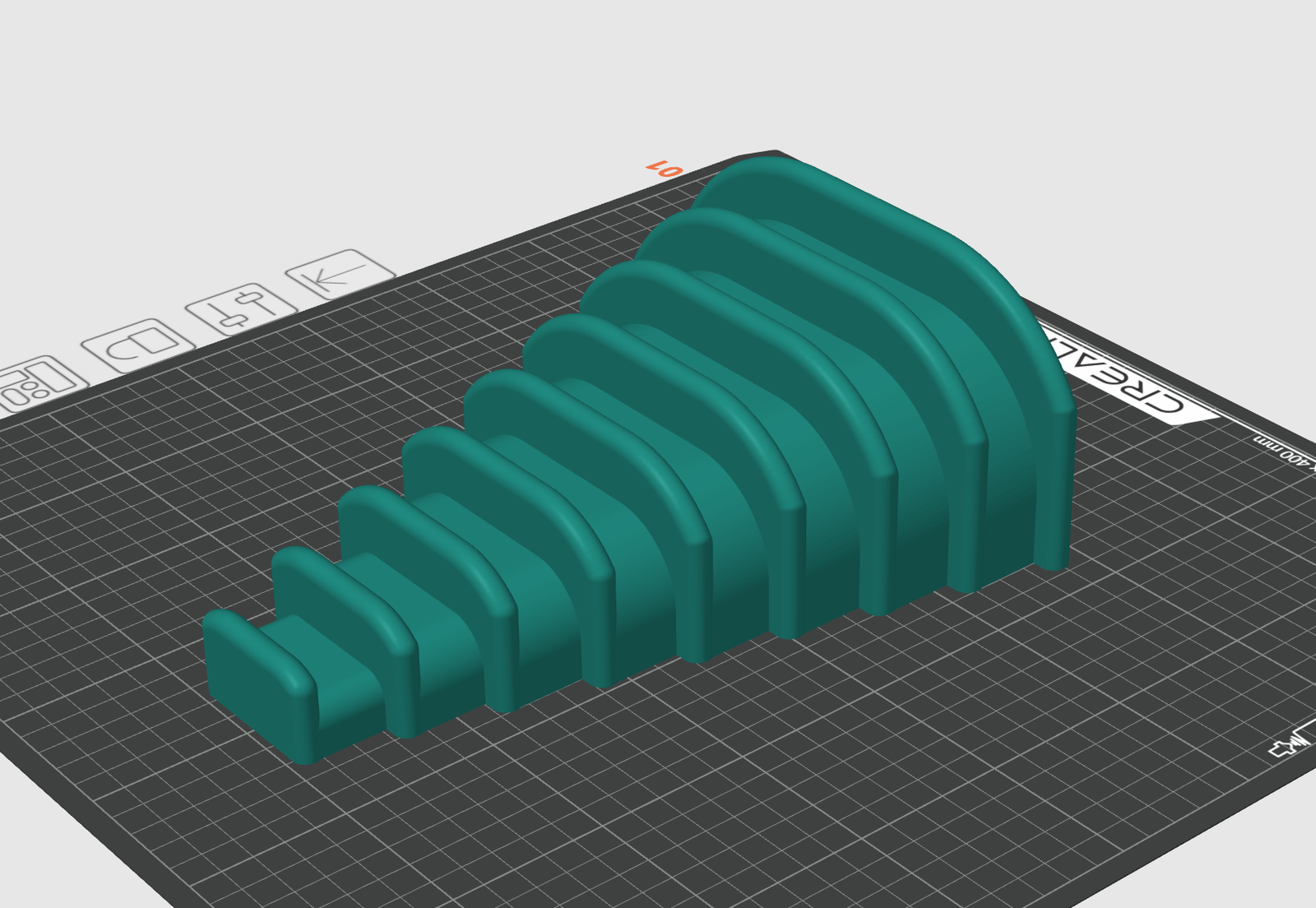

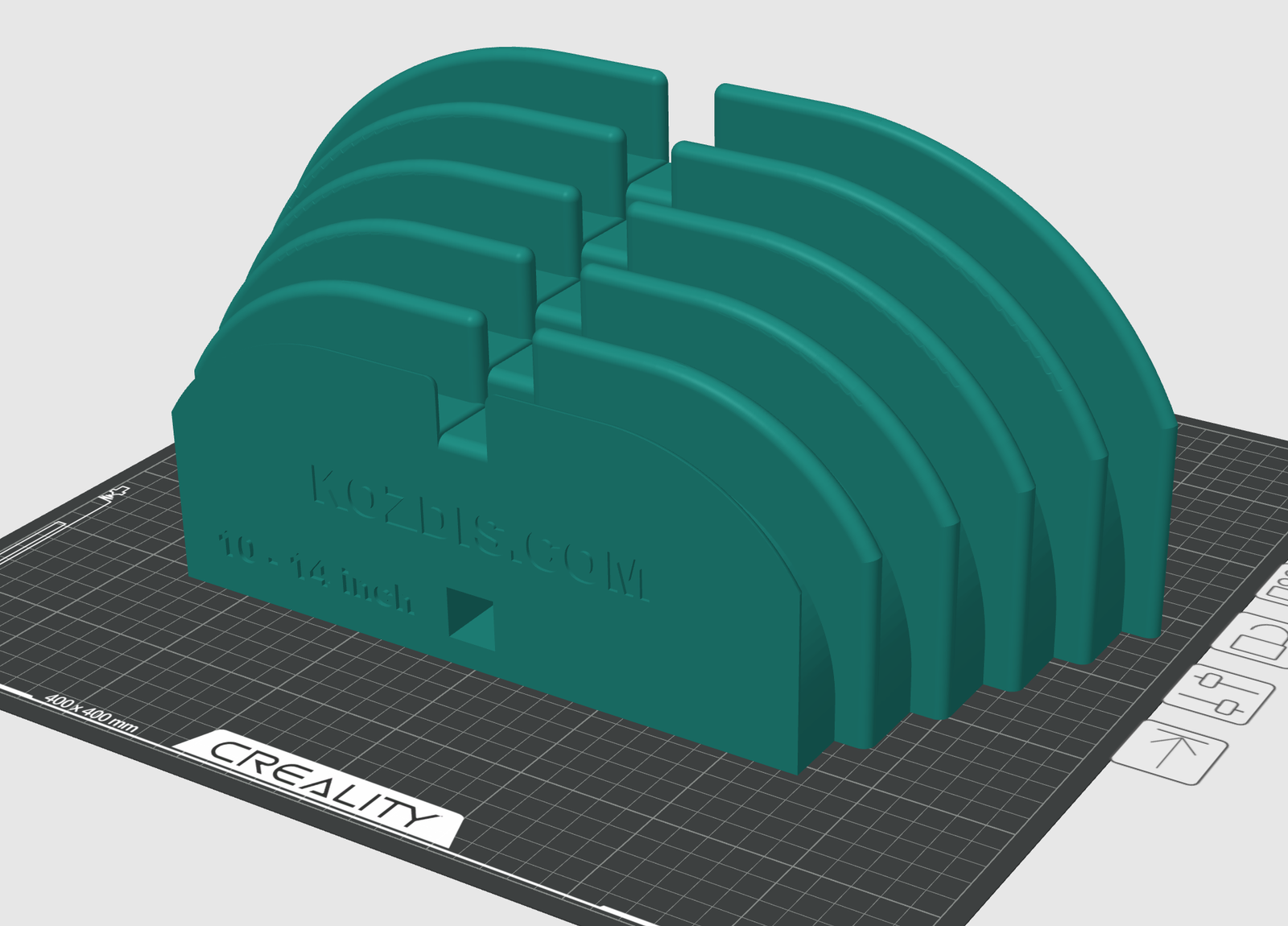

After years of limitations, technology finally allows us to accelerate and improve the coil winding process. Thanks to 3D printing, you can now have a coil winding head in any configuration — fully tailored to your needs.

The photos show that it’s possible to design a coil winding head for virtually any type of machine — both automatic systems (like Samatic) and manual winders. Thanks to 3D printing, each head can be precisely tailored to fit the dimensions, parameters, and technical requirements of your specific setup.

Sales of 3D-printed coil winding forms for both manual and automatic machines will be launched soon. Each customer will be able to customize parameters according to their specific needs. The forms have been tested and are continuously improved. They are suitable for rewinding motors from 1HP up to 250HP (the largest tested motor), with a maximum head width of 15 inches.

Feel free to reach out if you’d like more information about pricing or availability.

Visit my YouTube channel

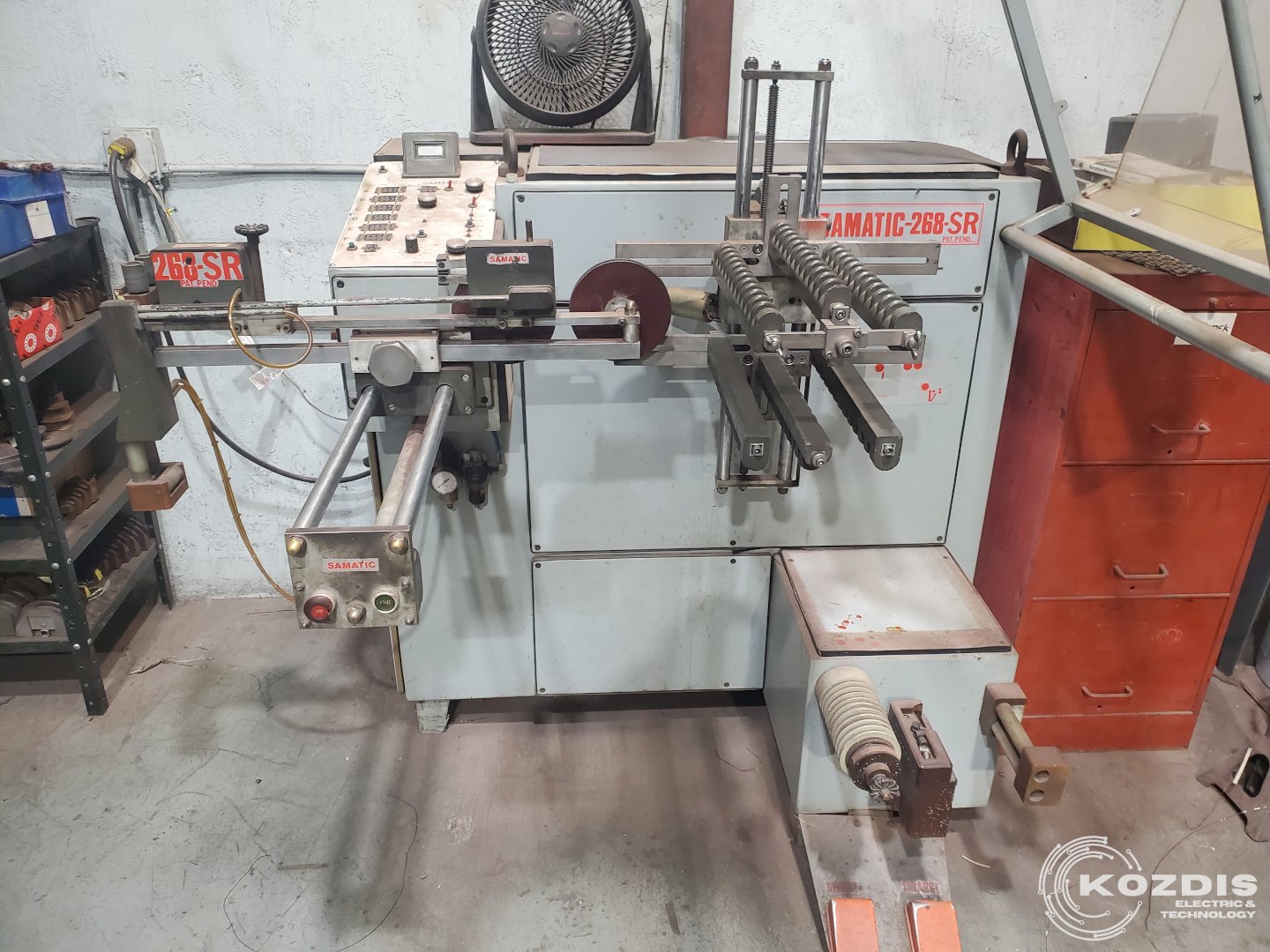

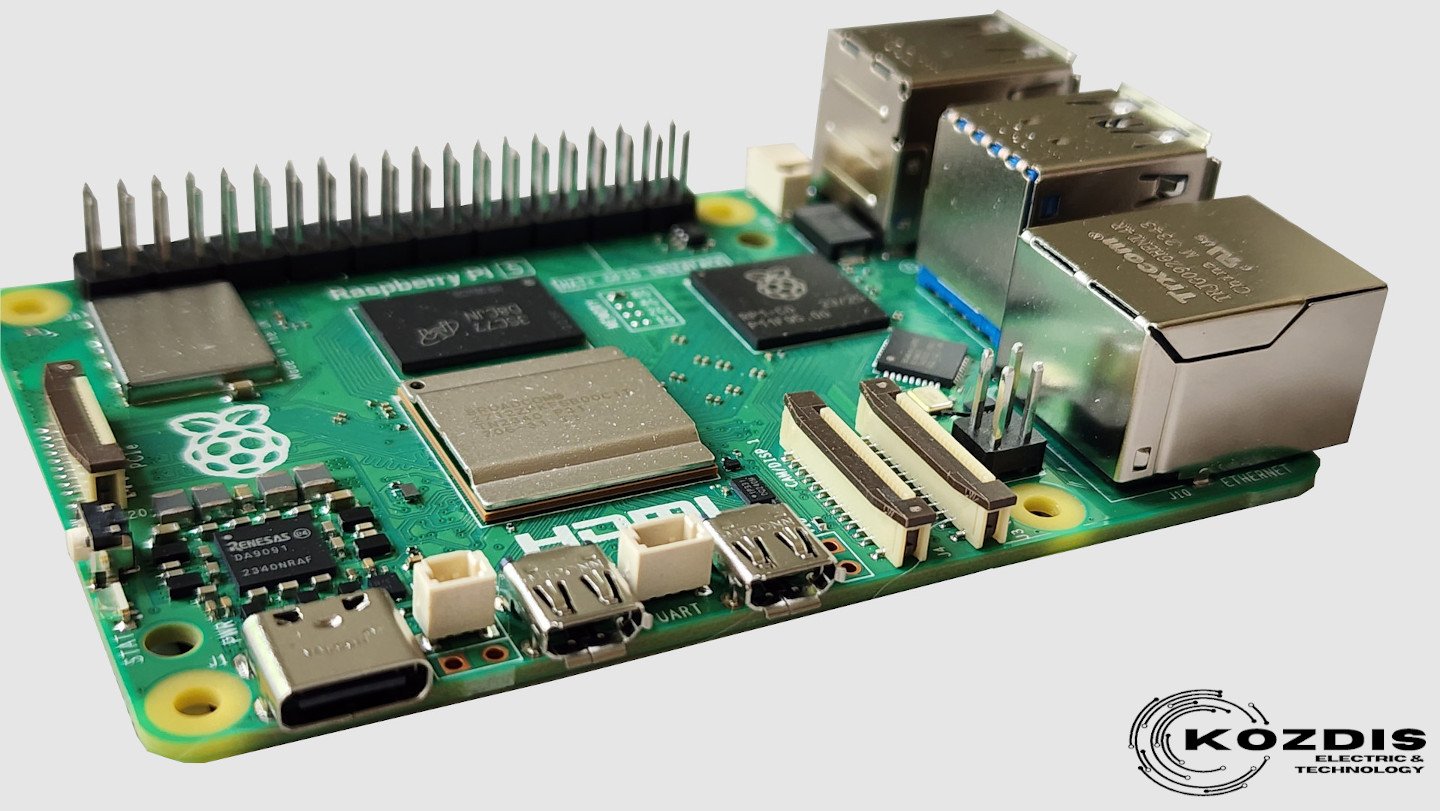

After four decades of reliable service, the coil winding machine finally succumbed to age and wear, breaking down without hope for easy repair. With the original manufacturer, SAMATIC, unable to supply the needed spare parts, the only conventional option left was purchasing a new machine priced at approximately $60,000. Facing this steep cost, I embarked on a project to restore the existing machine at a fraction of that price. By harnessing the power of a Raspberry Pi 5, I aimed not only to bring the machine back to life but also to integrate modern control and efficiency. Here’s how I achieved significant savings and breathed new life into an old workhorse.

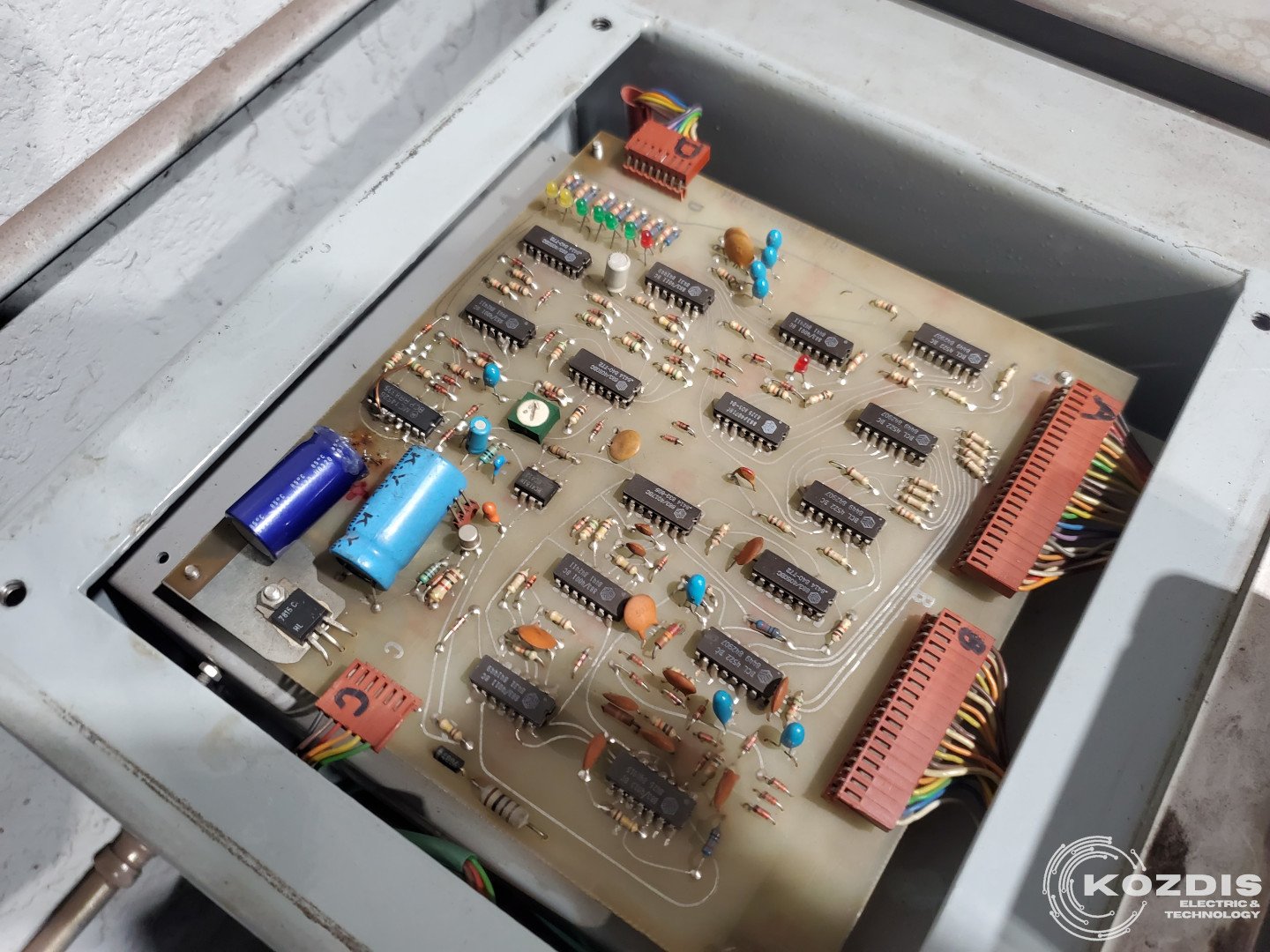

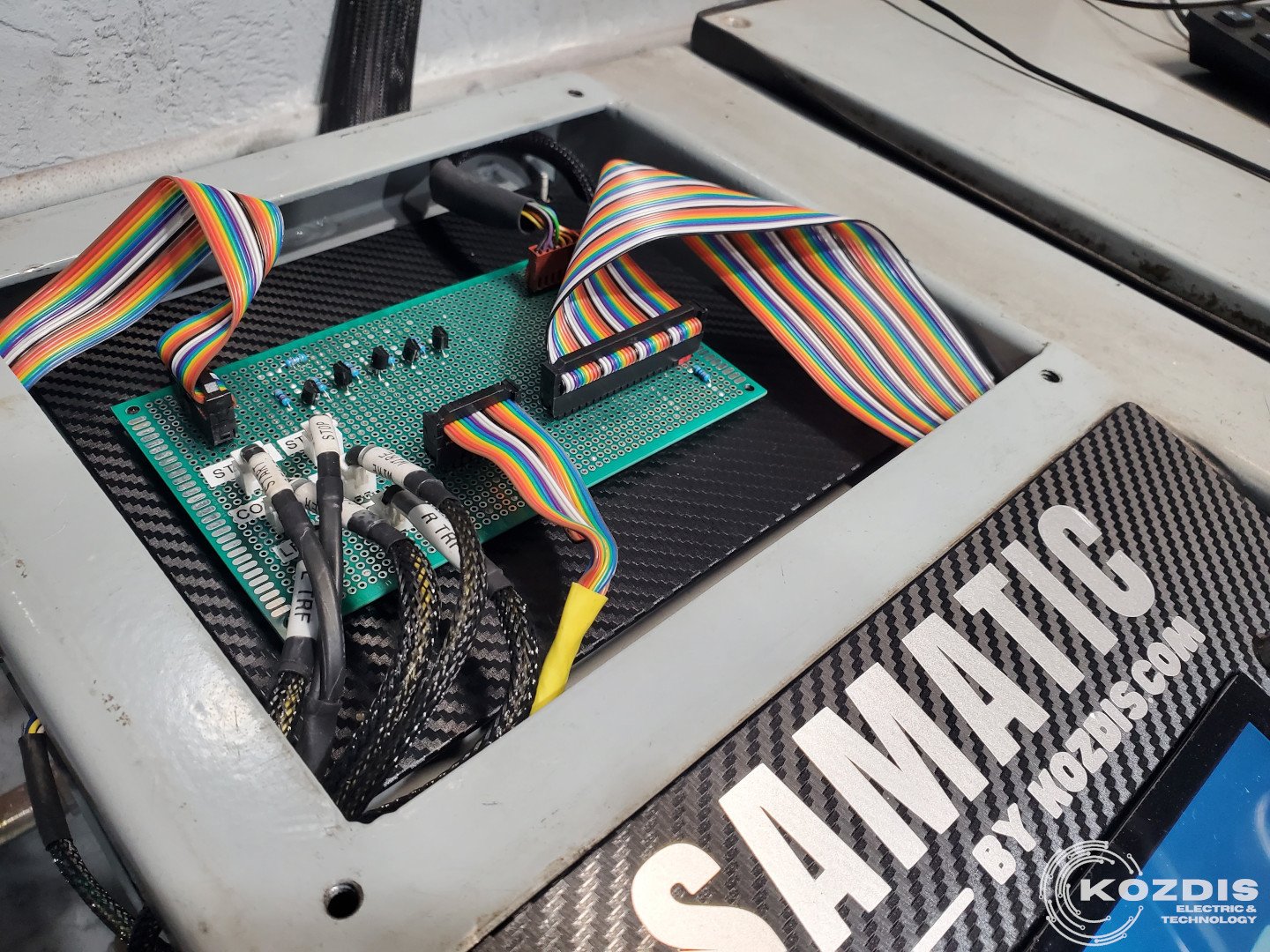

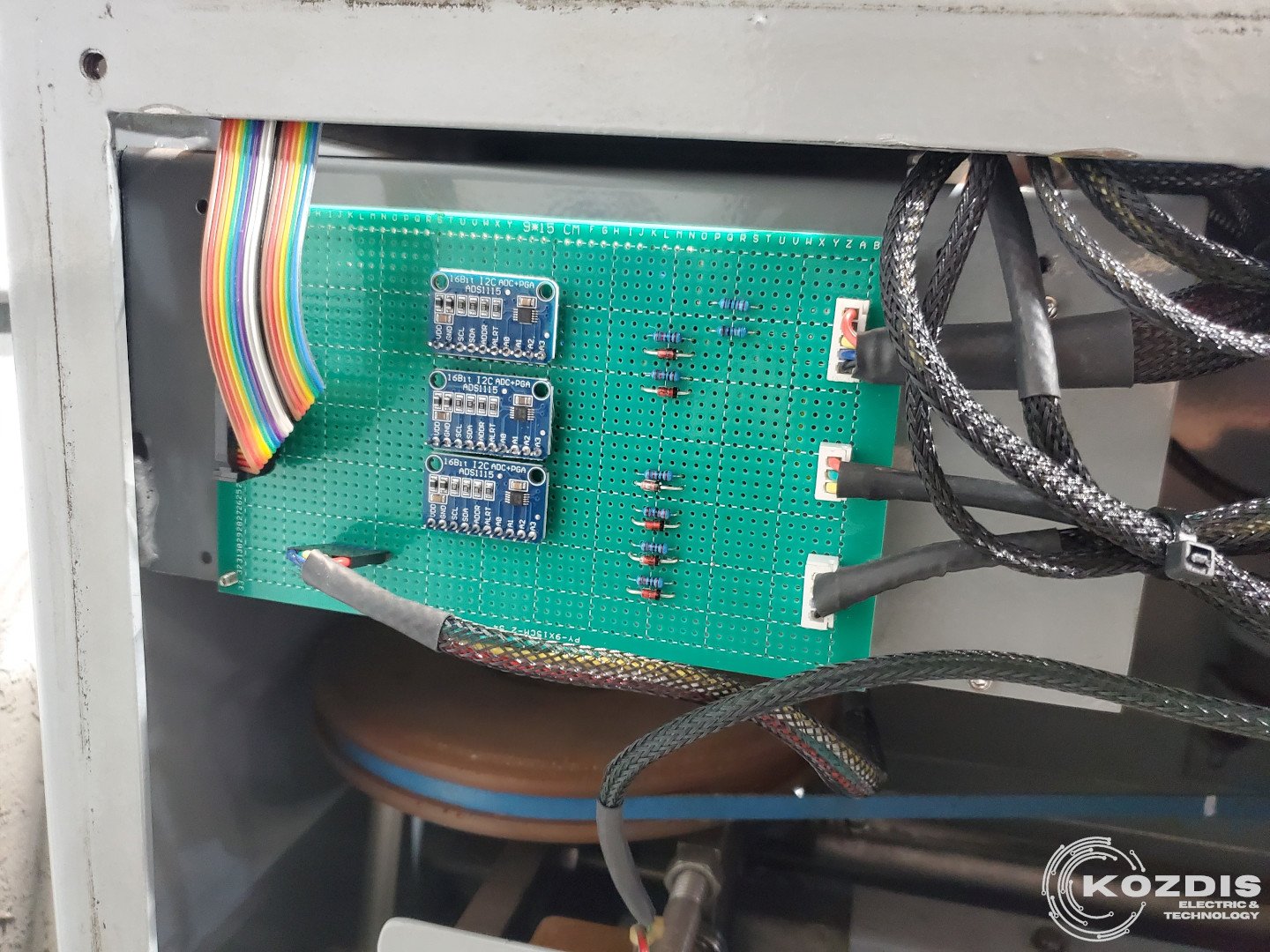

In the first picture, we see an old PCB that has been damaged. Despite replacing one of the components, the board still did not work. On the second, there is a new main PCB which is directly connected to the Raspberry Pi.

The old circuit board has been replaced with a new PCB, which works in conjunction with a tachometer, a stepper motor, and sensors responsible for controlling transitions between individual coils.

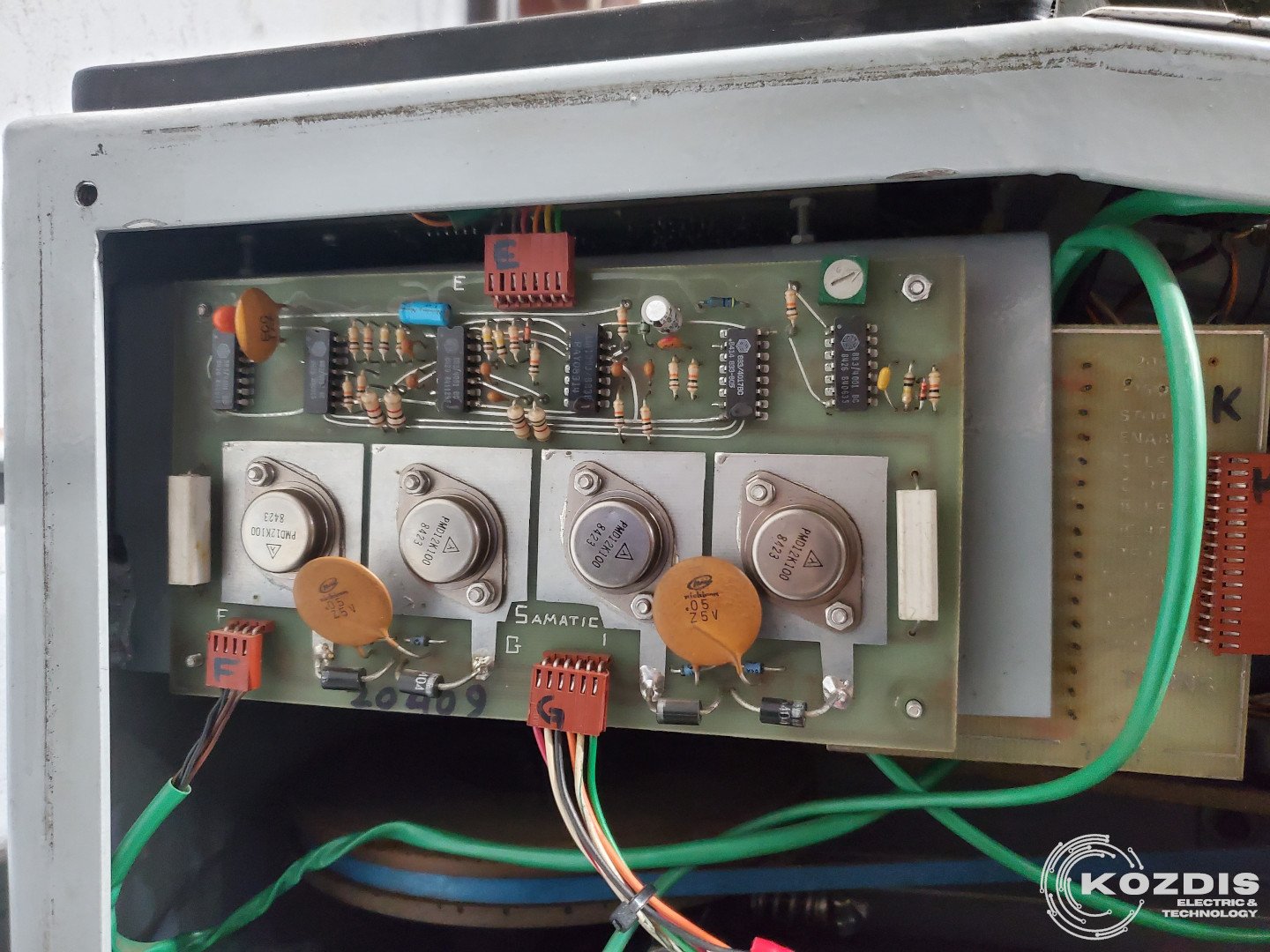

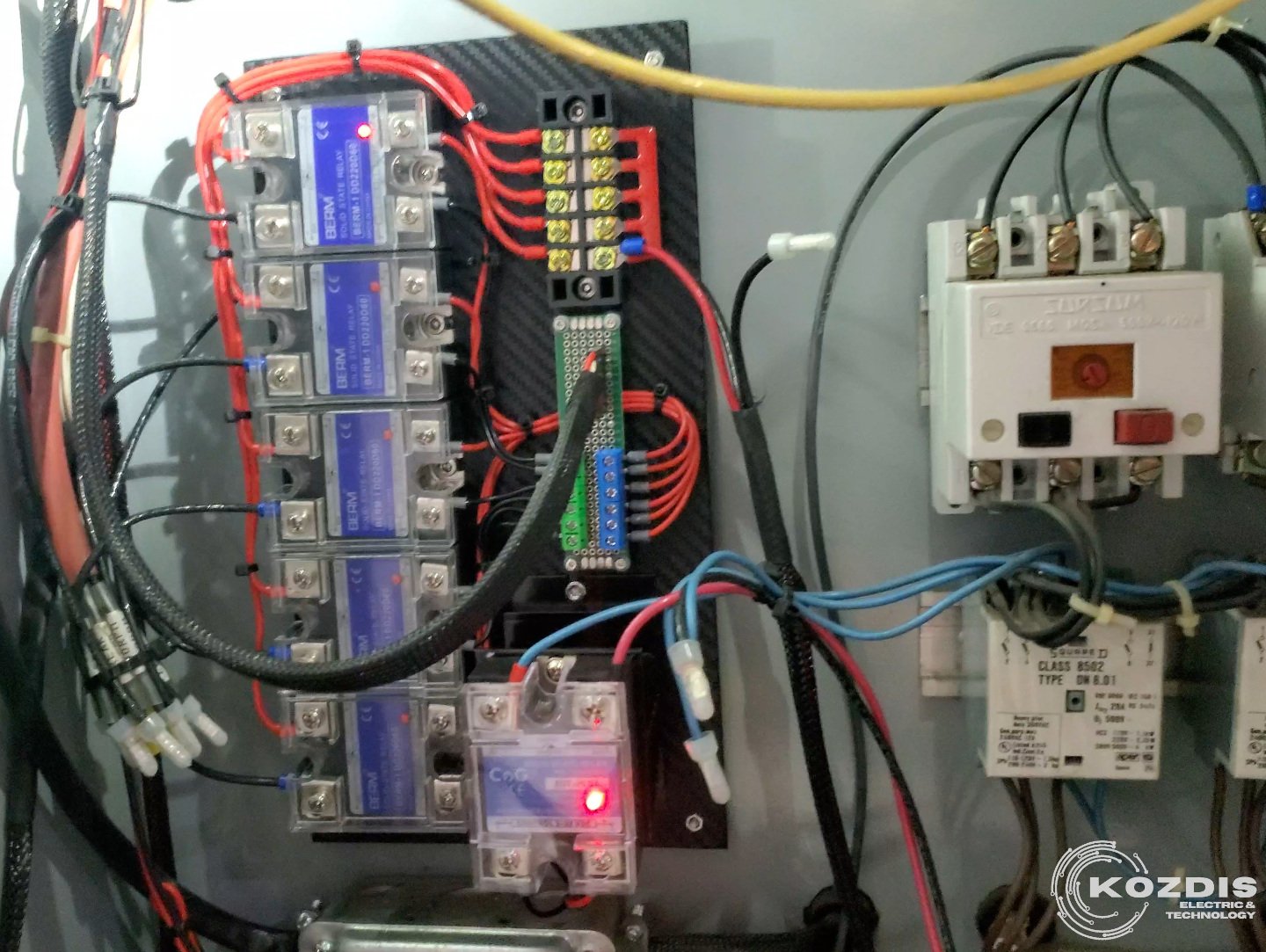

The new board contains Solid State Relays used to control the main motor and the clutches. It is responsible for managing the motor’s rotational speed and the precise engagement of the clutches during coil transitions.

We start with a look at the old control panel. The following images showcase a completely new panel equipped with a 10-inch touchscreen. The final image reveals the wiring connections and the heart of the machine — the Raspberry Pi 5.

After repair, the machine is powered by Raspberry Pi 5, which is visible in the first photo. This compact but powerful computer has two HDMI ports, which allowed me to install an additional monitor. The second photo shows the available external ports: 1x HDMI and 2x USB.

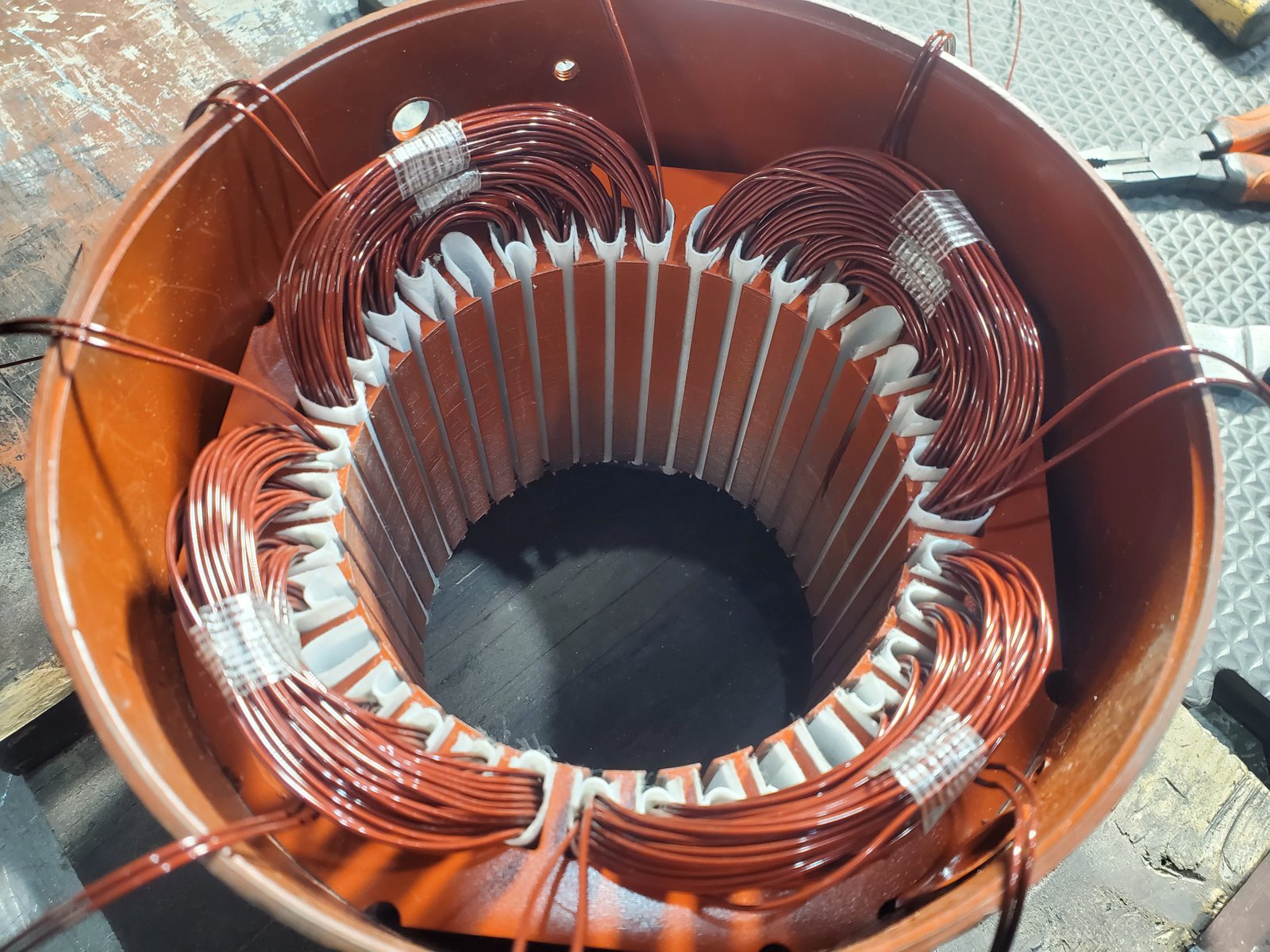

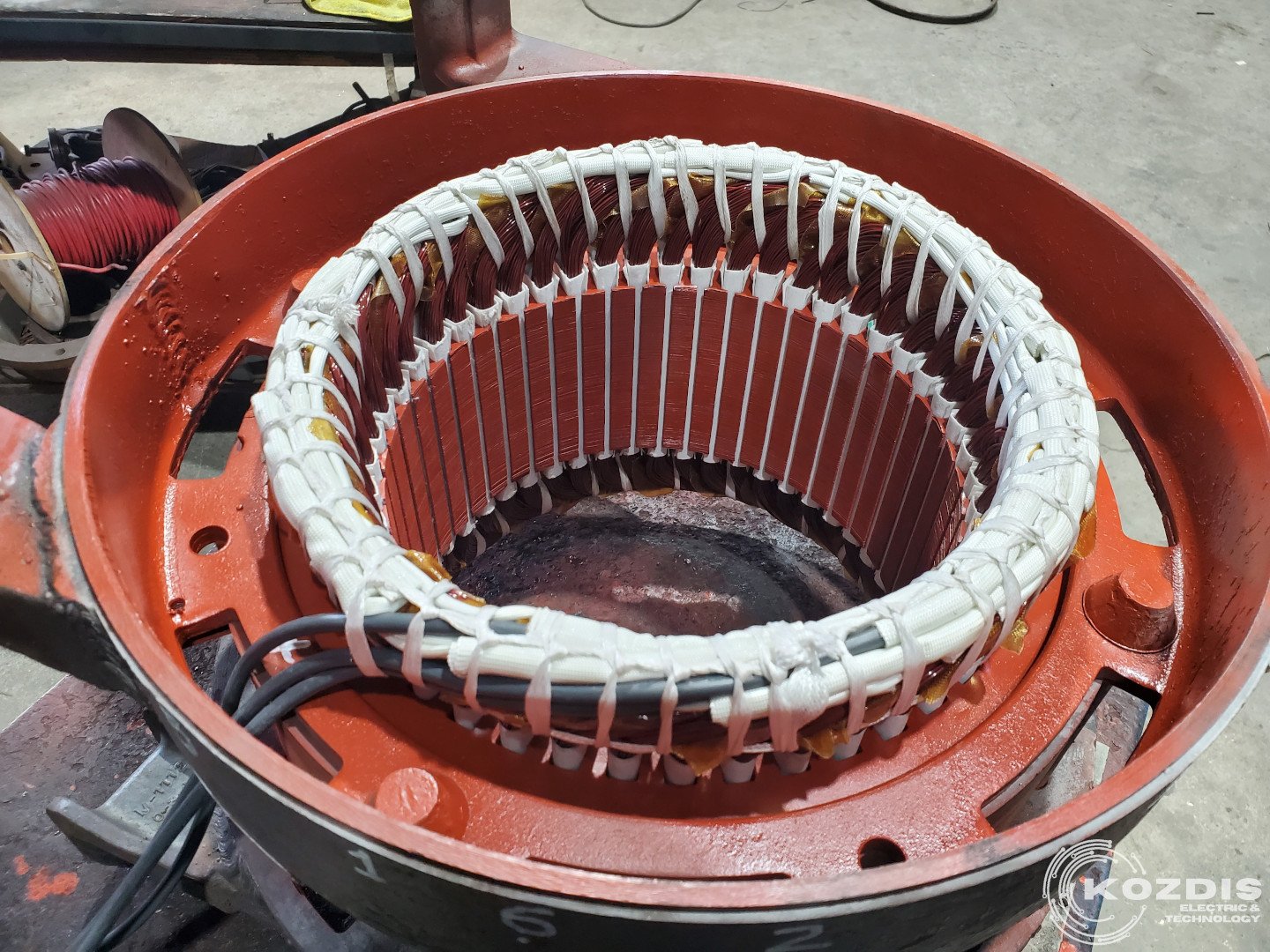

After the repair, the SAMATIC machine was immediately used to wind coils for a motor from HAUGHTON ELEVATOR. The motor is over 80 years old, and the brand's history dates back to 1867.

The first photo shows the motor stator prepared for winding. In the second, the coils have already been inserted and are ready for sewing.

The next stage of the repair shows the motor with cables routed, ready for varnish immersion. Following that, the motor is prepared for final assembly.

The fully restored 80-year-old motor has been given new life and is now ready to continue serving elevator passengers in Miami for many years to come. If you have motors in need of repair, don't hesitate to contact KLIMEK ELECTRIC MOTOR. With the help of modern technology like the Raspberry Pi 5, we bring even the oldest machines back to life.

Now you’ve seen how a 40-year-old machine can be repaired using Raspberry Pi 5, saving significant costs. If you're vacationing in Florida and staying in Miami, you might find yourself riding in an elevator powered by an electric motor that was restored with the help of Raspberry Pi 5.

After the renovation, the new machine winds coils for both AC and DC motors.

The first video demonstrates the winding of coils for an AC motor, while the second showcases the DC coil used for the elevator brake. We can adjust the speed of the stepper motor to match the wire thickness with the pitch.

KOZDIS Electric & Technology

Boca Raton, FL 33496

Copyright 2025 Kozdis Electric & Technology. All Right Reserved.